article

Off to Sydney!

Waagner-Biro Stage Systems goes Australia! The story behind the renovation of the Joan Sutherland Theater from 2015-2017.

Reading time: 6 min 19 sec

Anyone who thinks of Australia inevitably thinks of Sydney Opera House, which was designed by Danish architect Jørn Utzon. The opera house was inaugurated in 1973 by Queen Elizabeth II.

With more than 10.9 million visitors every year, it is one of the most visited centres for perform-ing arts, and Australia’s premier tourist attrac-tion.

The opera house contains five performance venues with a total of 5,541 seats: the concert hall with 2,688 seats, the Joan Sutherland Thea-ter (opera theater) with 1,547 seats, the drama theater with 544 seats, the playhouse with 398 seats and the Studio Theater with 364 seats.

Waagner-Biro Stage Systems has a long part-nership with the Sydney Opera. In the 1970s, the company received the incredibly prestigious order, which at the time contributed to Waagner-Biro's international breakthrough in the field of stage technology.

More than 40 years later, at the end of Decem-ber 2015, Waagner-Biro Stage Systems won the international competition for the renewal of the entire stage technology of the Joan Sutherland Theatre. The output to be delivered by Waagner-Biro includes the complete renewal of the upper stage machinery with more than 100 hoists, new backstage lifts, and the refurbishment of the orchestra lifts. An extremely short closure time of approx. six months for this comprehensive renovation posed a major challenge.

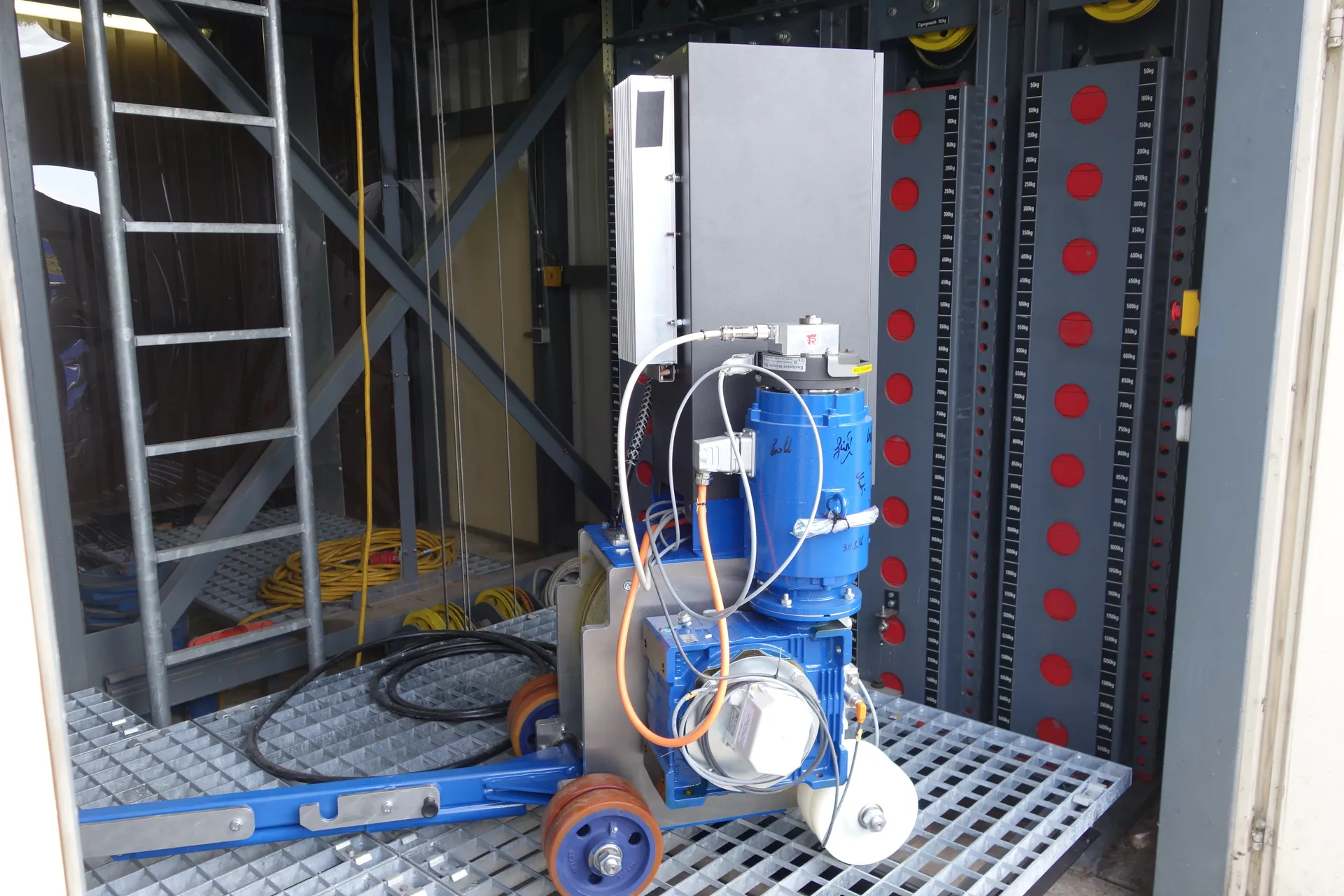

This project also included Factory Acceptance Tests (FAT). The FATs for the winches already took place in August 2016, in December 2016 the FATs of the lower stage machinery followed, which were shipped in January 2017.

The winches were successfully accepted by the customer at the FAT.

It must also be fun

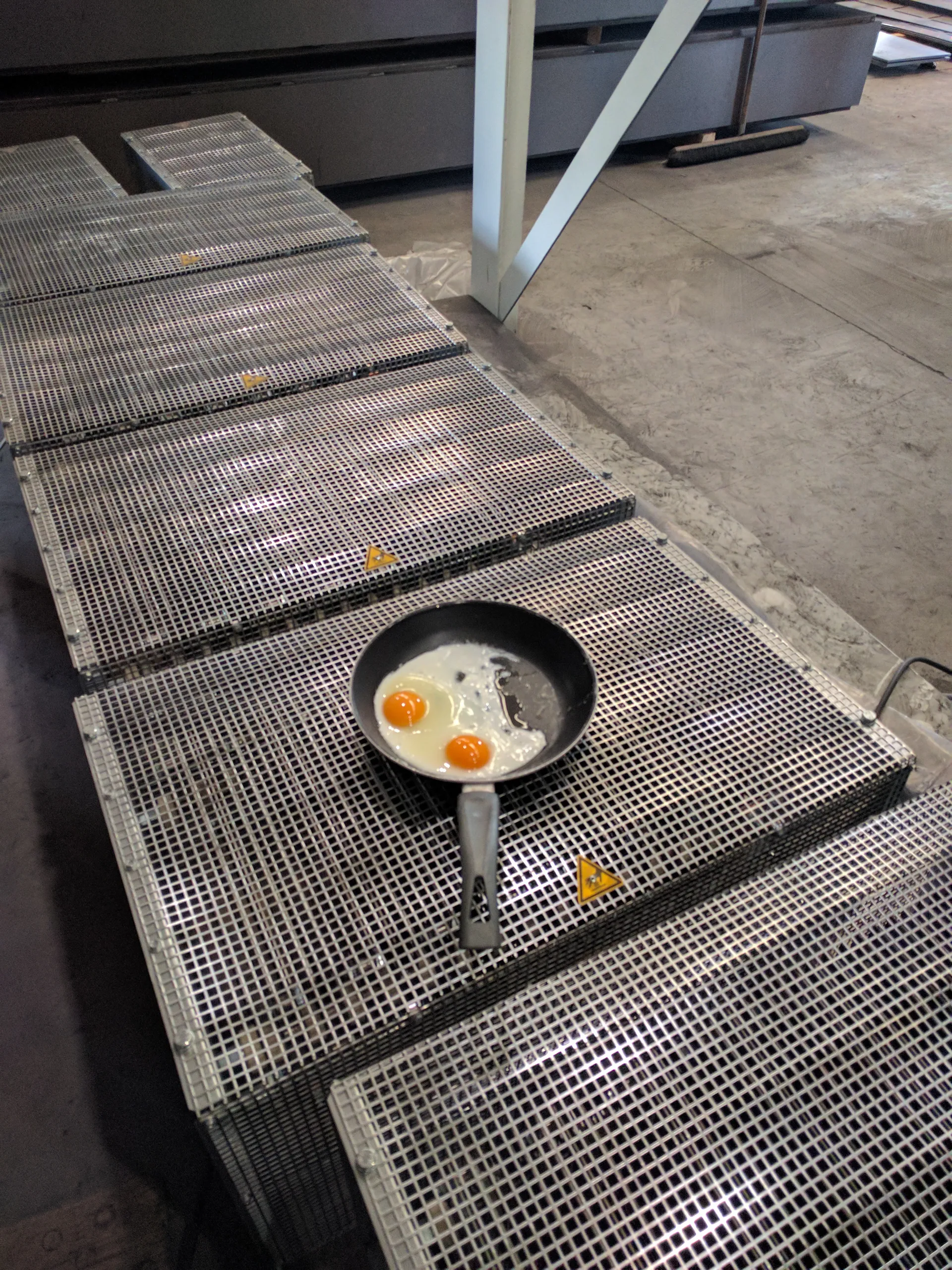

For the FAT of the lower stage machinery we constructed two platforms, each 11.4 x 3.6 m with a 10.6 M hub, weighing approx. 18 tonnes. For the testing phase a generator was hired which would normally be used for live TV broadcasts like the Hahnenkammraces in Kitz-bühel/Austria.

So we could also fry the odd egg as we were working.

Off to Sydney!

The construction site at the opera house started work on May 25, 2017.

As early as April 2017, it was time for some of our employees to pack their bags and move to Sydney – even with their families. With a time window of barely six months for the conversion and a time difference of ten hours, it required the presence of the Project Manager, the Installation Manager and a member of the Mechanical Departement. This team was also involved in the planning and the FATs. The client has set a date of 14/11/2017 for “Theatre machinery project works complete”.

After seven months of refitting, it was time for New Year's Eve: On December 31, 2017, the performance of the newly renovated Joan Sutherland Theater was raised with the performance "The Merry Widow".

Interview with Georg Seliger (mechanical department)

You will spend long periods of time in Australia. Why is that?

Waagner-Biro Stage Systems is replacing the theatre machinery in the Joan Sutherland Theatre at the Sydney Opera House. I have been working on this project as design engineer since the very beginning in the tender phase and will continue to support the construction manager on site.

Was it clear from the beginning that you would need to spend a lot of time abroad for this project?

It has been in discussion already in a very early phase of the project. For complex projects with a very short installation time like this one, it is definitely beneficial to have instant support from the design department on site, especially considering the time difference between Sydney and Vienna.

How did your wife react?

My wife has been very supportive and open-minded regarding moving to Australia for the project. Fortunately, we have been able to organize for her to join me in Sydney for most of the time. Both of us looked forward to spending some time abroad.

What kinds of things do you need to think about when you settle in a new place?

Apart from organisational matters, like getting a work visa and an apartment, I have to decide what to take with me for the next six months.

What particular challenges are you facing with this project?

The major challenge is the very short time frame for the installation. Not only the theatre machinery will be replaced, but also other parts like HVAC, audio/video systems and fire protection systems. Accommodating the new equipment in a limited space was the next challenge.

You got involved during the offer phase? Why is that, and what were you able to contribute?

To demonstrate Waagner-Biro Stage Systems qualifications and to show that we were the right partners for such a demanding job, we produced very extensive offer documents. I was responsible for making a design for the general arrangement of the upper stage equipment as well as load calculations and several other documents.

FATs (Factory Acceptance Test) were carried out. What was the reason for this?

During last year we did two FATs for this project in Austria. One for the upper stage winches, while the other one included a complete setup of the new rear stage elevators, including equalisers and safety barriers. During these tests, the equipment was entirely assembled and commissioned in order to confirm their functionality and test all the required functions of winches and elevators.

Construction of the podiums for the FAT (11.4 x 3.6 m with a hub of 10.6 m and a weight of 18 tons).

What is the organisational process for FATs, what has to be done beforehand and how long does it take to carry out a FAT, or to organise it?

Due to the size of the lower stage equipment, the first issue was to find a location where we could build up the entire system. After finishing the shop drawings and manufacturing the parts, the elevators were assembled, commissioned and tested internally over a period of approx. two months. Parallel to that, a testing program was developed and coordinated with our client and the theatre consultant of the project.

What are the advantages of FATs?

The main advantage of a FAT is that you get the certainty that the equipment fits and works as it is supposed to do. We also had the chance to refine some of the mechanical, electrical and control-related aspects of the elevators. Furthermore we were able to test some of the special control modes, something that would usually not happen until the final commissioning on site. The FAT definitely facilitates the installation, which is very beneficial considering the very limited time we have on site.

When you conduct FATs, is the client also there on site?

A few parties were present during the FAT, including the client, the theatre consultant, and the managing contractor of the renovation project.

©Waagner-Biro Stage Systems

©Waagner-Biro Stage SystemsInes Schwabl

Author

©Waagner-Biro Stage Systems

©Waagner-Biro Stage SystemsAngelika Albert-Knaus

Author

7/14/2025

In this article

Waagner Biro Stage